What is a cabin cylinder ?

The text discloses an overturning oil cabin cylinder of an automobile cab, which comprises a polyurethane buffer ring, a pin shaft, a lever assembly, a clamping groove, a piston rod, a cylinder barrel, an oil cab cylinder base, an oil cab cylinder of a limiting device, a U-shaped bracket and an upper support , stops, rod joints, undamped ports, backup rings, DU bushings, guides and pistons. The new model has excellent performance, can effectively avoid the disengagement and lowering of the lever assembly, is efficient and fast, has high safety performance and good sealing performance; At the same time, the DU bushing has good lubricity, reducing the resistance of the piston rod and reducing energy consumption; it is equipped with a polyurethane buffer ring, which has good elasticity and wear resistance, and has a certain buffering effect, which can prevent the rust, at the same time easy to disassemble and maintain; there is no damping oil port, which can effectively control the oil return of the rodless cavity too fast, resulting in large descending jitter and unstable speed.

1 . An overturning oil cab cylinder for an automobile cab, comprising a pin shaft (2), a lever assembly (3), a piston rod (5), a cylinder barrel (6), an oil cylinder

The base (7), the upper support (10), the piston rod joint (12) and the piston (17) are characterized in that: the top of the oil cylinder base (7) is fixed

The piston rod (5) and the cylinder barrel (6) are fixedly connected, and a piston (17) and a guide device (16) are arranged between the piston rod (5) and the cylinder barrel (6);

The top of the piston (17) is fixedly connected to the support ring (14), and the outside of the guide device (16) is wrapped by the DU bushing (15);

The top end of the cabin cylinder barrel (6) is connected to the piston rod joint (12), and a non-damping oil port is provided between the cab cylinder barrel (6) and the piston rod joint

(13); the top surface of the piston rod (5) is provided with a clamping groove (4), and the top end of the piston rod (5) is fixedly connected to the lever assembly (3); the

The top end of the lever assembly (3) is fixedly connected to the upper support (10), and the lever assembly (3) is connected to the upper support (10) through the pin shaft (2); the

The bottom end of the pin shaft (2) is provided with a polyurethane buffer ring (1), the surface of the upper support (10) is provided with a limiting device (11), and the limiting device

(11) Connect the limiting device cab cylinder (8); a U-shaped bracket (9) with an R-shaped circular groove is provided on the surface of the upper support (10).

2 . The overturning cabin cylinder of an automobile cab according to claim 1, characterized in that: the oil cab cylinder base (7)

A cylinder barrel (6) with a cylindrical structure is welded at the top.

3 . The overturning oil cabin tilt cylinder of an automobile cab according to claim 1 , characterized in that: the lever assembly (3)

It is connected with the piston rod (5) and the upper support (10) through a pin shaft (2) with a polyurethane buffer ring (1).

4. The overturning oil cab tilt cylinder of an automobile cab according to claim 1, characterized in that: the guide device (16)

It is fixed on the surface of the piston rod (5), and the guide device (16) and the cabin tilt cylinder barrel (6) are connected by screw threads.

5 . The overturning oil cab tilt cylinder of an automobile cab according to claim 1 , wherein the U-shaped bracket (9) is welded

It is connected to the surface of the upper support (10), and the limiting device (11) is hinged on the surface of the upper support (10).

6 . The overturning oil cab tilt cylinder of an automobile cab according to claim 1, characterized in that: the upper support (10) is made of

A semicircular structure is used, and the surface of the upper support (10) is connected to the lever assembly (3) through the pin shaft (2).

7 . The overturning oil cabin cylinder of an automobile cab according to claim 1 , wherein the support ring (14) is a

The end is fixed on the surface of the piston (17), and the annular structure at the other end of the support ring (14) is in contact with the cylinder (6).

8 . The overturning oil cylinder of an automobile cab according to claim 1 , characterized in that: the piston rod joint

(12) A mushroom head structure is adopted, and the bottom end of the piston rod joint (12) is connected to the cylinder barrel (6).

technical field

The utility model relates to a kind of overturning oil cylinder, is specially a kind of overturning oil cylinder of automobile cab, belongs to automobile design

field of application technology.

Background technique

The hydraulic overturning mechanism of the cab is powered by hydraulic pressure, and through the expansion and contraction of the hydraulic cab cylinder, the cab is made to revolve around the overturning axis.

Limited rotation, so as to complete the lifting and falling of the cab; the overturning cab tilt cylinder assembly converts hydraulic energy into mechanical energy,

It is a hydraulic actuator for linear reciprocating motion; its structure is simple and its work is reliable. When it is used to realize the overturning of the cab, it can be

It eliminates the need for reduction gear and has no transmission clearance, so it is widely loved by people in the automotive industry.

When the hydraulic overturning mechanism of existing cab is in operation, the vibration is large, and it is easy to cause the sliding of the lever assembly, in addition by

Due to the frequent expansion and contraction of the piston rod, it is easy to cause the wear of the cylinder, resulting in the leakage of hydraulic oil. When the piston rod falls back, the no rod cavity returns.

If the oil is too fast, it is easy to fall and shake, causing the speed to be unstable. Therefore, in view of the above problems, a kind of automobile cab is proposed.

Flip the cylinder over.

The purpose of this text is just to provide a kind of overturning oil cab cylinder of automobile cab in order to solve the above problem.

The text realizes above-mentioned object through the following technical solutions, a kind of overturning oil cylinder of automobile cab, including

Including pin shaft, lever assembly, piston rod, cabin cylinder barrel, oil cylinder base, upper support, piston rod joint and piston, the top of the oil cylinder base

The piston rod and the cylinder are fixedly connected, and a piston and a guide device are arranged between the piston rod and the cylinder; the top of the piston is fixedly connected

connected to the support ring, the outside of the guide device is wrapped by the DU bushing; the top end of the cylinder is connected to the piston rod joint, and the cylinder is connected to the

There is no damping oil port between the plug rod joints; the top surface of the piston rod is provided with a clamping groove, and the top of the piston rod is fixed with a connecting rod

rod assembly; the top of the lever assembly is fixedly connected to the upper support, and the lever assembly is connected to the upper support through a pin; the bottom of the pin

The end is provided with a polyurethane buffer ring, the surface of the upper support is provided with a limit device, and the limit device is connected to the limit device cylinder; the

A U-shaped bracket with an R-shaped circular groove is arranged on the surface of the upper support.

Preferably, the cylinder barrel of the cylindrical structure is welded at the top of the oil cabin cylinder base.

Preferably, between described lever assembly and piston rod, upper support, all are connected by the pin shaft with polyurethane buffer ring

catch.

[0008] Preferably, the guide device is fixed on the surface of the piston rod, and a threaded connection is adopted between the guide device and the cylinder.

[0009] Preferably, the U-shaped bracket is welded on the surface of the upper support, and the upper support surface is hinged with the limiting device.

Preferably, described upper bearing adopts semicircular structure, and upper bearing surface connects lever assembly by pin shaft.

Preferably, one end of the support ring is fixed on the piston surface, and the annular structure at the other end of the support ring is connected to the cab tilt cylinder touch.

Preferably, described piston rod joint adopts mushroom head structure, and piston rod joint bottom end connects cabin cylinder.

The beneficial effect of the present utility model is: the overturning oil cabin tilt cylinder of this kind of automobile cab has excellent performance, long life, and may have

Effectively avoid the disengagement and lowering of the lever assembly, efficient and fast, high safety performance and good sealing performance; equipped with DU bushing and support

Ring, which plays a good sealing role, supports and orients at the same time, prevents wear caused by eccentric load, and the DU bushing has a good Lubricity, reduce piston rod resistance, reduce energy consumption; equipped with polyurethane buffer ring, has good elasticity and wear resistance, has a certain

Excellent buffering effect, can prevent rust, and at the same time facilitate disassembly and maintenance; there is no damping oil port, which can effectively control the return of the rodless cavity

The oil is too fast, resulting in the phenomenon of large descending jitter and unstable speed; the limit device is provided, which can effectively prevent the lever assembly from advancing.

It has good economic and social benefits and is suitable for popularization and use.

Description of drawings

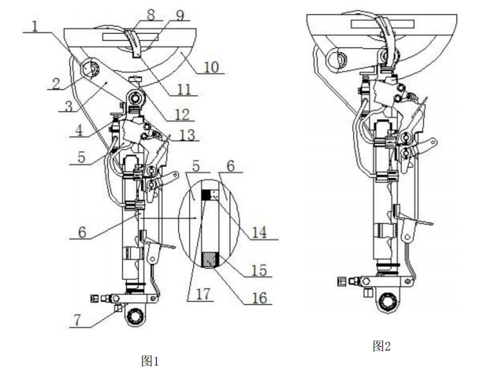

1, polyurethane buffer ring, 2, pin shaft, 3, lever assembly, 4, snap groove, 5, piston rod, 6, cylinder, 7, oil cylinder bottom

Seat, 8, Limit device cylinder, 9, U-shaped bracket, 10, Upper support, 11, Limit device, 12, Piston rod joint, 13, No damping oil

Port, 14, Support Ring, 15, DU Bushing, 16, Guide, 17, Piston.

detailed description

Below in conjunction with the accompanying drawings in the embodiments of the present utility model, the technical solutions in the embodiments of the present utility model are carried out

Clearly and completely described, obviously, the described embodiments are only a part of the embodiments of the present invention, but not all

Example. Based on the embodiments of the present utility model, those of ordinary skill in the art will not make creative work under the premise

All other embodiments obtained belong to the protection scope of the present invention.

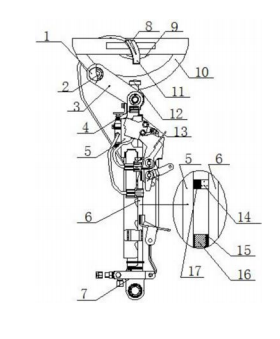

Please refer to shown in Figure 1-2, a kind of overturning oil cylinder of automobile cab, comprises pin 2, lever assembly 3, piston rod 5,

The cylinder barrel 6, the oil cab cylinder base 7, the upper support 10, the piston rod joint 12 and the piston 17, the top of the oil cylinder base 7 is fixedly connected to the piston rod

5 and the cylinder 6, a piston 17 and a guide device 16 are arranged between the piston rod 5 and the cylinder 6; the top of the piston 17 is fixedly connected

The support ring 14 can effectively support the piston rod 5 when it is stretched, and is wear-resistant to prevent the cylinder 6 from being worn out.

The outer part is wrapped by the DU bushing 15 to avoid the wear of the cabin cylinder 6 and at the same time has a good lubrication effect; the top of the cylinder 6 is connected to the

The plug rod joint 12, the piston rod joint 12 is in the shape of a mushroom head, and there is no damping oil between the cabin cylinder barrel 6 and the piston rod joint 12

Port 13, which can control the oil return of the rodless cavity too fast, resulting in large descending jitter and unstable speed; the top surface of the piston rod 5 is hollowed out

The slot 4, the top of the piston rod 5 is fixedly connected to the lever assembly 3; the top of the lever assembly 3 is fixedly connected to the upper support 10, the

The lever assembly 3 is connected to the upper support 10 through a pin shaft 2; the bottom end of the pin shaft 2 is provided with a polyurethane buffer ring 1, which is rust-proof and has buffering

function, the upper support 10 is provided with a limiting device 11 on the surface, the limiting device 11 can be engaged in the interior of the slot 4, the limiting device 11

The device 11 is connected to the limit device oil cab tilt cylinder 8, the limit device oil cylinder 8 is connected to the cylinder barrel 6, and the limit device 11 is driven to prevent the piston rod 5

The upper support 10 is provided with a U-shaped bracket 9 with an R-shaped circular groove on the surface.

As a kind of technical optimization scheme of the present utility model, the cab tilt cylinder of described oil cylinder base 7 top welding cylindrical structure

6, the connection is stable.

As a kind of technical optimization scheme of the present utility model, between described lever assembly 3 and piston rod 5, upper support 10

All are connected by pin 2 with polyurethane buffer ring 1 to prevent rust and have good buffering effect.

As a kind of technical optimization scheme of the present utility model, described guide device 16 is fixed on the surface of piston rod 5, and guides

Threaded connection is adopted between the thrust device 16 and the cylinder barrel 6, the sealing effect is good, and relative movement does not occur, and the guiding performance is high.

As a kind of technical optimization scheme of the present invention, described U-shaped bracket 9 is welded on the surface of upper support 10, and the upper

A limit device 11 is hinged on the surface of the support 10, which can achieve a good limit and prevent the piston rod 5 from sliding down.

As a kind of technical optimization scheme of the present utility model, described upper support 10 adopts semicircular structure, and upper support

10 The surface is connected to the lever assembly 3 through the pin 2, which is convenient for installation. As a kind of technical optimization scheme of the present utility model, one end of described support ring 14 is fixed on piston 17 surface, and

The annular structure at the other end of the support ring 14 is in contact with the cylinder tube 6 , which has a good supporting effect and prevents the cylinder tube 6 from being worn.

As a kind of technical optimization scheme of the present invention, described piston rod joint 12 adopts mushroom head structure, and flexible

The bottom end of the plug rod joint 12 is connected to the cab tilt cylinder barrel 6 to facilitate the connection and fixation of the piston rod joint 12 and the U-shaped bracket 9 of the upper support 10 .

When the utility model is in use, the overturning oil cylinder of this kind of automobile cab is by turning on the oil pump power supply, when the oil pump place

In the rising state, the hydraulic oil enters the rodless cavity of the oil cab tilt cylinder and pushes the piston rod 5 to rise, so that the top of the piston rod 5 is in the coordination of the lever assembly 3.

Raise the surface of the U-shaped bracket 9 in the same way, and fit with the U-shaped bracket 9, the cab starts to turn upward, and the piston rod joint 12 gradually

Entering into the R-shaped circular groove of the U-shaped bracket 9, the piston rod joint 12 acts through the U-shaped bracket 9, and is locked by the limit device 11 at this time.

It is closed in the slot 4 to limit the position, so that the upper support 10 and the lever assembly 3 will not be disengaged; when the cab falls, the piston rod joint 12

Rotate out the U-shaped bracket 9, the piston rod 5 descends into the inside of the rodless cavity and enters the cylinder barrel 6, and the non-damping oil port 13 can prevent the oil from returning too fast, causing

The descending vibration is large and the speed is not stable, so that the piston rod 5 returns to the initial position.

For those skilled in the art, it is obvious that the present invention is not limited to the details of the above-mentioned exemplary embodiments, but

And without departing from the spirit or basic characteristics of the present invention, the present invention can be realized in other specific forms.

type. Therefore, the embodiments should be regarded as exemplary and non-restrictive in all respects, and the present invention

The scope of the type is defined by the appended claims, rather than the foregoing description, and is therefore intended to cover the scope of equivalents falling within the claims.

All changes within the meaning and scope are included in the present invention. Any reference signs in the claims shall not be construed as limiting

the claims involved.

In addition, it should be understood that although this specification is described in terms of embodiments, not every embodiment only includes

Contains an independent technical solution, this description in the description is only for the sake of clarity, those skilled in the art should

Taking the description as a whole, the technical solutions in each embodiment can also be appropriately combined to form a person skilled in the art.

Other implementations that can be understood.