Quickly learn about hydraulic cylinders for dump trucks and trucks

Friends who have repaired the car must have used jacks, especially the small body of the hydraulic jack can support hundreds of times its own weight. In the field of dump trucks and trucks, there is also such a "hercules". Whether it is a small agricultural dump truck or a large truck weighing hundreds of tons, you can see it. And just need to touch the button lightly, even heavy objects can easily lift up, as if there is always endless strength, it is a hydraulic cylinder.

Hydraulic cylinders for dump truck trucks, i.e. Hydraulic Tilt cylinder

For dump trucks, the importance of the lifting mechanism is just like the saddle in drop-and-hook transportation. With it, the transportation efficiency of the vehicle can be greatly improved. Some people may be wondering why a small hydraulic lifting mechanism can be so amazing? What's the secret? After we talked about the suspension system of the dump truck last time. Today, Hualong will take you to talk about the hydraulic lift of dump truck.

Small body, high energy, Hydraulic Tilt cylinder

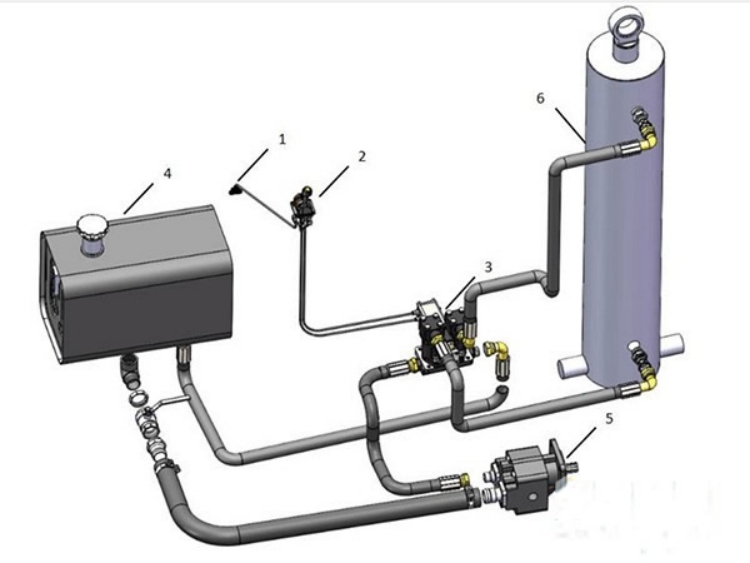

As we all know, due to the incompressible nature of liquids, they are often used in various hydraulic transmission systems. For hydraulic lifts used in dump trucks, they usually consist of 5 parts, which are cylinder And cylinder heads, pistons and rods, seals, cushioning, and exhaust. And its working principle is very simple, it is basically equivalent to an enlarged version of the jack.

Structural diagram of hydraulic lifter for dump truck Structural diagram of hydraulic lifter for dump truck

The hydraulic lifter uses a hydraulic pump to pass hydraulic oil through a single valve into the cylinder. At this time, the hydraulic oil entering the cylinder cannot be backed up due to the single valve. The cylinder rod is forced upward, and then the work continues to make the hydraulic oil continuously enter the hydraulic cylinder. In this way, it continuously rises, and when it is going to lower, it opens the hydraulic valve to return the hydraulic oil to the fuel tank.

Although the principles of hydraulic lifts are the same, hydraulic lifts with different structures have been developed. There are three main types of dump trucks commonly used, namely the center-mounted double-cylinder lifting mechanism, the double-sided side lift lifting mechanism, Front top lifting structure.

Mid-Twin Hydraulic Tilt cylinder

The center-mounted double-cylinder lift is installed with a multi-stage hydraulic oil cylinder (usually 3 ~ 4 levels) on both sides of the front of the second axle of the vehicle. The upper fulcrum of the hydraulic cylinder acts directly on the chassis of the carriage. However, the center-mounted parallel bar lift will put a lot of pressure on the chassis and the entire lifting system during work, and the lifting stability is relatively poor.

Double-sided rollover hydraulic lift Double-sided rollover Hydraulic Tilt cylinder

Then there is the double-sided rollover hydraulic lift. Unlike the center-mounted double-cylinder lift, the two cylinders of the double-sided rollover hydraulic lift are arranged vertically at the chassis of the vehicle. The stroke of the oil cylinder can be greatly reduced, and it can also achieve double-side rollover lifting, but it also has certain defects. It is prone to rollover accidents during lifting.

Ranch

The last is the front-type lifting mechanism. Because of its simple structure and good stability, it is also a lifting method commonly used in dump truck products.